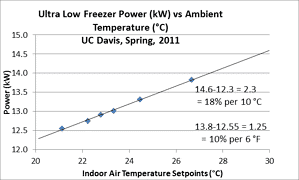

Written by Tim Van Slambrouck, VP of Sales & Marketing, DENT Instruments Normally, one thinks of a biological research facility as a place where research is done on organic material only. But that’s only part of the story at University of California at Davis. It turns out that the university’s labs are also where some interesting ad hoc research is happening relating to the efficiency and management of refrigeration technologies. UC Davis researchers use about 1,000 ultra-low temperature (ULT) freezers, each one holding biological samples – some of them key samples from their life’s work. The freezers also represent a significant expense item for the university, often costing between $8,000 and $10,000 to purchase, and consuming more electricity than a typical home—when running well. Worse yet, an old, inefficient “zombie freezer” may consume the same amount, even though one-sixth the size. At 26 kWh per day and $0.10 per kWh, this adds about $80/month to the University’s electric bill. Even though freezers provide an essential service to research, there is often no strategy to find the old, bad performers, and little has been verified about manufacturers’ claims of energy efficiency, so measuring electricity consumption by the customer is essential. Allen Doyle, sustainability manager, has taken on measurements of new and old freezers, and freezer manufacturers and lab managers in campuses and federal laboratories nationwide are interested in the results. “We want to buy the top quartile of new equipment and retire or repair the bottom quartile of old equipment,” said Doyle. “In addition, freezer manufacturers want to know that the products are meeting their published specs, and we want to motivate the freezer industry to manufacture the most energy-efficient freezers possible. New ultra low temperature freezers should consume less than 40-45 Watts per cubic foot of interior volume, and old freezers should be repaired or retired if they consume more than 50-60 Watts per cubic foot,” continued Doyle. “Also, many scientists were not previously concerned with the energy efficiency of their research,” said Doyle. “Now the data is available to enable them to make beneficial changes.” With all the focus on the results, it’s critical that quality power measurement equipment is used to gather the data. For that purpose, Allen Doyle chose the ELITEpro XC portable energy data logger by DENT Instruments of Bend, Oregon. The ELITEpro XC can be equipped with up to four current sensors ranging from split core current transformer style to flexible Rogowski “rope” style CTs. Using the ELITEpro XC, Doyle has been studying the relationships between freezer energy consumption and ambient temperature in the freezer rooms. The graph in Figure 2 shows that it pays to keep the intake air cool, saving about 0.5% per degree reduction in ambient temperature. Power consumption data can either be device-specific, or measured at an electrical panel. In this test the meter was placed in the electrical panel and it measured the main feed for about ten freezer circuits. New to the ELITEpro XC are 4 analog input channels which can be configured for voltage or current input used in any combination among channels. Analog inputs are especially helpful when used in conjunction with power measurements to correlate the consumption of electricity with environmental (i.e. temperature and humidity), HVAC performance, or other process conditions. The results suggest to Doyle that rooms full of freezers (freezer farms) should be designed much like IT data centers for air conditioning, and should be configured with hot air behind the freezers that rises to the ceiling return ducts, while cool air needs to be directed in front of the freezers. The space between freezers should be blocked off. Doyle points out this is the opposite of what is typically written in the owner’s manuals. “Freezer manufactures usually recommend, ‘be sure to allow 6-8” all around the freezer for air circulation,’” said Doyle. “This is unmanaged air flow, leading to warm air being pulled into the intake, and excessive run time, power draw and air conditioning needed. Just by directing the hot air to the returns, a freezer farm can see a 5-10% energy reduction.” With precise measurement instrumentation such as the DENT ELITEpro energy logger monitoring energy use, UC Davis’s biology laboratories have become “green laboratories.” And the policies in place at UC Davis have caught the attention of manufacturers. With efficient new freezers, retiring old freezers, and operating them most efficiently, UC Davis could save tens of thousands of dollars in electricity each year. The really big picture is that plug load in modern molecular biology laboratories can average under 2 Watts per square foot for an entire floor. Even equipment rooms are only about 10 W/SF. This has dramatic implications for downsizing and locating cooling vents and air conditioner downsizing. “Other university labs would be well-served by putting DENT equipment into service,” concludes Doyle.” To add action to his conviction, Doyle is launching a green laboratory certification program which touches on several different areas including water use and disposal of chemicals in addition to energy consumption. “It’s a very in-depth green lab certification process,” said Doyle. Referring to the US construction industry’s Leadership in Energy & Environmental Design (LEED) program, Allen says that UC Davis green labs program is “like LEED for Labs: Operations and Maintenance.” ♦ Download a PDF copy of this story here.